STOP OFF-PAINTS

Stop-off paints for gas carburising, low pressure carburising, gas nitriding, nitrocarburising, plasma-/pulse plasma nitriding and annealing processes.

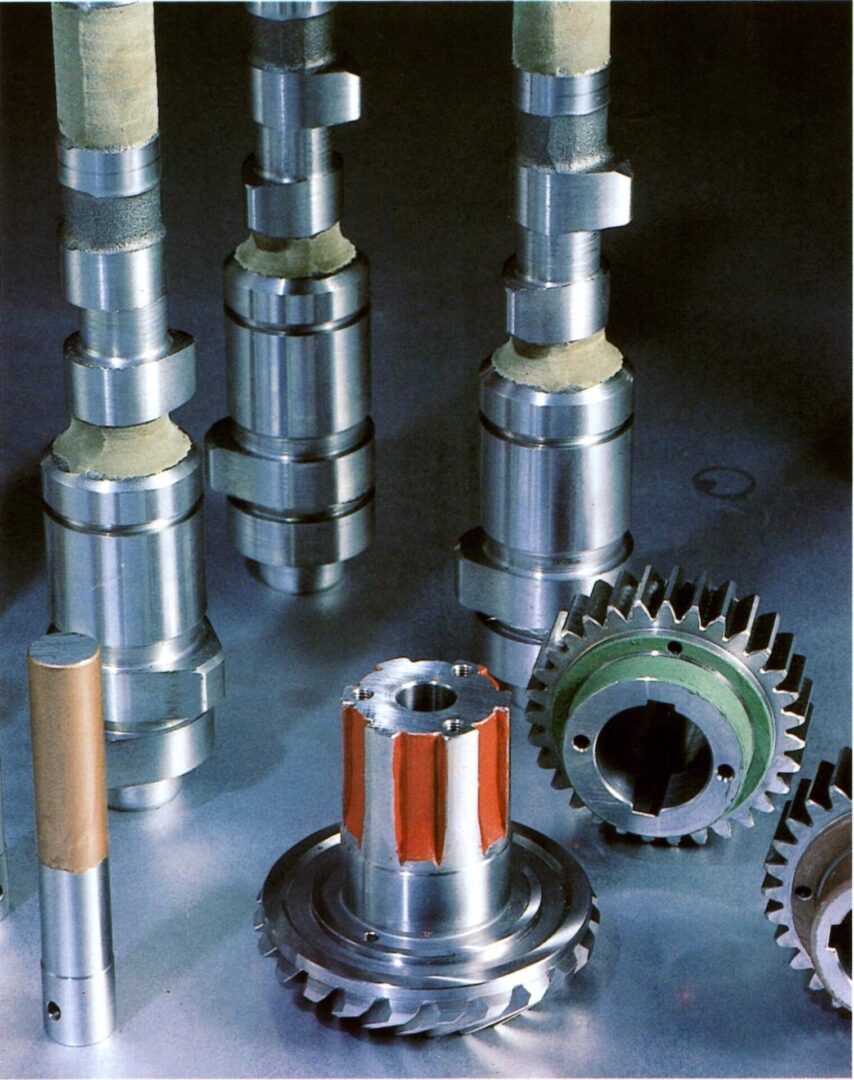

Carburising and nitriding processes are based on the thermochemical diffusion of carbon and/or nitrogen into the surface layer of heat-treated components.

CONDURSAL, CONDURON, and VACUCOAT stop-off paints set standards when high-quality and complex components have to be protected gas-tight against diffusion in defined areas during heat treatment. This is to enable subsequent processing steps, such as machining, forming or welding, in individual cases also to minimise the risk of cracks during truing, especially in the area of thread tips or punctures. The unsurpassed high product quality, based on the use of modern manufacturing and testing methods, provides a process-reliable protection. In addition, the excellent productivity of the stop-off paints enables a particularly economical and resource-saving application.

Application can be carried out by brushing, dipping, spraying, stamping or by customer-specific procedures to suit customer’s requirements.

We also offer special thinners, adapted to the respective product to ensure the consistency in regard to the customer’s specific need.

STOP-OFF PAINTS FOR SELECTIVE CARBURIZING AND CARBONITRIDING

CONDUSAL 0090 / First choice for applications requiring removal by washing

- Suitable for case depths up to .080"

- Solvent based paint

- One (1) coat coverage

- Residues can be removed easily by washing with hot water or alkaline

- Can be applied by brush, spray or dipping

- Will not glaze your furnace interior

CONDURSAL 777 Alternative when a solvent based paint is not an option

- Suitable for case depths up to .080”

- Free of solvents

- One (1) coat coverage

- Residues can be removed easily removed by washing with hot water or alkaline

- Can be applied by brush, spray or dipping

SOLVENT FREE STOP-OFF PAINTS FOR SELECTIVE CARBURIZING ONLY

CONDURSAL 710 is the most widely used paint

- Suitable for to case depths up to .120"

- One (1) coat coverage

- Non-hazardous

- Can be applied by brush, spray or dipping

- Removal by shot blasting or wire brush

- Will not glaze your furnace interior

CONDURON G55 is extremely effective for deep case carburizing

- Effective for case depths up to .225"

- Two (2) coat coverage

- Non-hazardous

- Can be applied by brush, spray or dipping

- Removal by shot blasting or wire brush

- Will not glaze your furnace interior

CONDURON G55HK / A special modification of CONDURON G55

- Effective for case depths up to .225"

- Two (2) coat coverage

- Non-hazardous

- Can be applied by brush, spray or dipping

- Removal by shot blasting or wire brush

- Will not glaze your furnace interior

CONDURON 33 is a newly formulated deep case carburizing paint

- Offers enhanced adherence to steel surface. Can be used in carburize only applications, cooled in air, reheated and quenched without re-coating between cycles.

- Effective up to case depths of .170”

- Two (2) coat coverage

- Non-hazardous

- Can be applied by brush, spray or dipping

- Removal by shot blasting or wire brush

CONDURON 160 is an extremely effective paint for case depths above .200”

- Two (2) coat coverage

- No solvents

- No labeling obligation

- Non-hazardous

- Can be applied by brush, spray or dipping

- Removal by shot blasting or wire brush

STOP-OFF PAINT FOR SELECTIVE VACUUM CARBURIZING

- Solvent-based paint

- Strong adherence to the steel surface

- Reliable protection up to case depths of .160" (4mm)

- Extremely low vapor pressure of the coating ingredients

STOP-OFF PAINT FOR SELECTIVE NITRIDING & NITROCARBURIZING

CONDURSAL N623p solvent free stop-off paint

- Water Based- Environment friendly

- Suitable for Nitriding cycles up to 90 hours

- Temperature range: 930 Degrees F – 1150 degrees F

- No special thinners required

- Application by painting, spraying and immersion

- Removal by steel brush or blasting

CONDURSAL N523 solvent based stop-off paint

- Dries quickly

- Suitable for Nitriding cycles up to 90 hours

- Temperature range: 930 Degrees F – 1150 degrees F

- Application by painting, spraying and immersion

- Removal by steel brush or blasting

STOP-OFF PAINTS FOR SELECTIVE PLASMANITRIDING & PULSE-PLASMANITRIDING

- Solvent-based paint

- For temperatures of 750 – 1085 degrees F

- Excellent electric conductivity

- Normally one (1) coat coverage is required

- Easily removed after heat treatment by brushing or wiping

- Application by brush or dipping

- Solvent-based paint

- For temperatures of 750 – 1085 degrees F

- Free of copper and conductive materials

- Does not exhibit conductivity

- Normally one (1) coat coverage is required

- Easily removed after heat treatment by brushing or wiping

- Application by brush or dipping

STOP-OFF PAINTS FOR SCALE PREVENTION

CONDURSAL Z0095/ Prevents oxidation and scale between 1200F - 1562F

- Solvent-based paint

- Good for temperatures between to 1562 degrees F

- Removal of residues by washing with hot water or alkaline

- Application by brush or dipping

CONDURSAL Z1100 / Prevents scale between 1200F – 2000F

- Solvent-based anti-scaling protective lacquer

- Good for temperatures between 1200F min. – 2000F max.

- Removal of residues, if any, by steel brush

- Application by brush or dipping

WHITE LABEL THINNER

For Use with: Condursal 0090, N523, N9, N9W, Z0095, Z1100, Vacucoat 0095

- WARNING: FLAMMABLE

- Stir Before Using & Close container when not in use

YELLOW LABEL THINNER

For Use with: Condursal 710, G55, G55HK, 33, 160

- Stir Before Using & Close container when not in use