Protective Lacquer against Oxidation and Scaling

suitable up to 1.100°C

- CONDURSAL Z1100 provides very efficient protection against oxidation and scaling during

- austenitizing and annealing with oxygen present. It can be used for temperatures ranging between

- 600 and 1.100°C. It is suitable for many kinds of metallic materials such as constructional steels,

- tool steels, austenitic steels, castings, and it withstands annealing times up to 7 hours and more.

- Up to temperatures of approx. 850°C, the residues of CONDURSAL Z1100 pop off after heat

- treatment; hence no cleaning of the workpieces is necessary in this case.

- After annealing at temperatures exceeding 850°C, light brushing with a steel brush is sufficient to

- remove the residues and to provide clean surfaces (no sandblasting required).

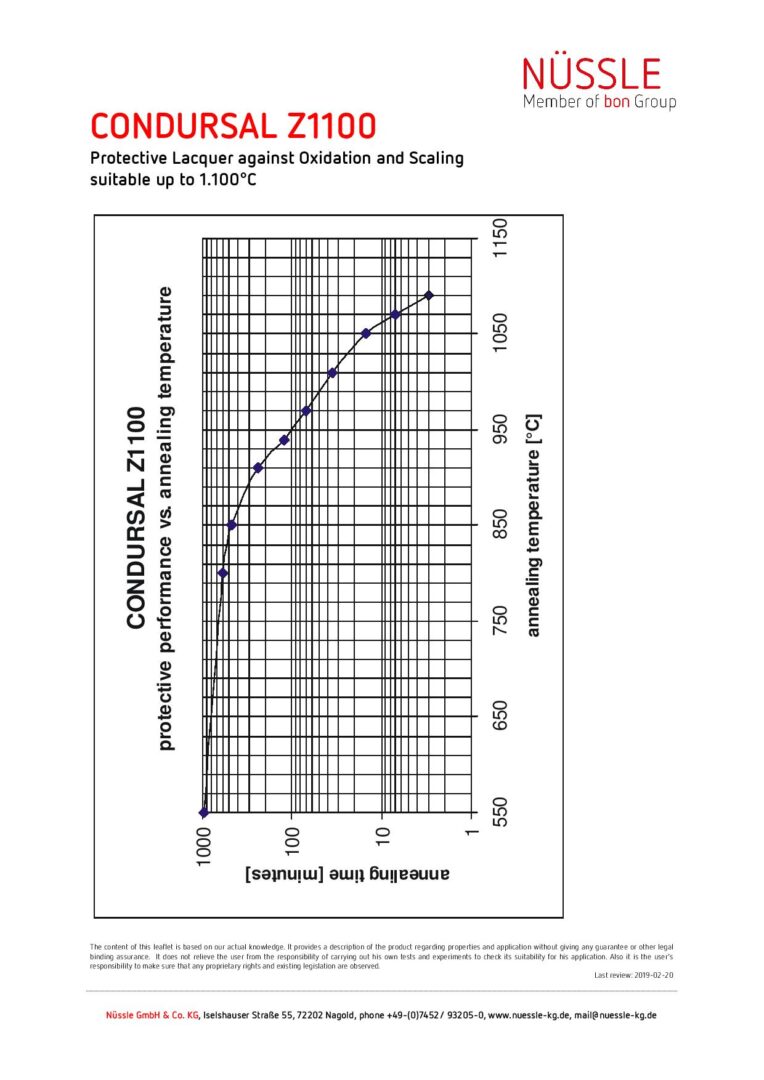

CONDURSAL Z1100 provides very efficient protection against oxidation and scaling during austenitizing and annealing with oxygen present. It can be used for temperatures ranging between 600 and 1.100°C. It is suitable for many kinds of metallic materials such as constructional steels, tool steels, austenitic steels, castings and it withstands annealing times up to 7 hours and more.

Up to temperatures of approx. 850°C, the residues of CONDURSAL Z1100 pop off after heat treatment; hence no cleaning of the workpieces is necessary in this case.

After annealing at temperatures exceeding 850°C, light brushing with a steel brush is sufficient to remove the residues and to provide clean surfaces (no sandblasting required).

Surfaces to be protected must be clean, free of oxides, scale, dust, rust, oil, grease and other contaminants, which is normally achieved by either sandblasting or alkaline washing (formerly also by vapor degrasing).

Prior to use, stir the contents of the CONDURSAL Z1100 tin thoroughly. After getting a homogeneous consistency CONDURSAL Z1100 is ready for use. Application to the workpieces can be achieved by painting, immersion or spraying. Normally, there is only one thin coating of approx. 15µm thickness necessary for optimum protection.

It is important to provide a smooth coating of uniform thickness. Applying the paint in a layer of excessive thickness may result in popping-off problems and thus should be avoided. For extended annealing times a second thin coating is recommended. It should be applied not earlier than after thorough drying of the first one has been accomplished. Drying time for each coating is about 10 minutes.

Removal of residues

Once heat treatment is finished, the residues of CONDURSAL Z1100 pop off of their own or can be removed easily using a steel brush (see above).

Tins of CONDURSAL Z1100 should be closed airtight after use to prevent the solvent of the lacquer from evaporating. To clean brushes, spraying pistols and other equipment, the “SPECIAL THINNER FOR CONDURSAL Z1100" or Xylene can be used but by no means water.

Special advice

1. Excessive thickness of the coating may result in popping-off and poor protection.

2. CONDURSAL Z1100 is not suitable for temperatures below 600°C; at such low temperatures it behaves like a heat-proof lacquer leaving a black coating on the surface of the workpieces, which can hardly be removed after annealing.

CONDURSAL Z1100

CONDURSAL Z0095 Instructions For Use:

Condursal Z0095 provides excellent protection for steel components against oxidation during heat treatment up to temperatures of 1600° F maximum. Condursal Z0095 is easy to apply, residues can be easily removed by washing in hot water.

Surfaces of the work pieces to be protected must be free of oil, grease and dirt, which can be achieved by alkaline washing or degreasing with chlorinated solvents.

Prior to using Condursal Z0095, it must be thoroughly mixed. The paint can then be applied with a brush or by immersion. Flat brushes with soft bristles are best suited for brush application.

The paint must be applied in a continuous coat of even thickness of .008" to .012".

Normally one coat is sufficient for effective protection.

For optimum protection, it is necessary that the coating be completely dry before placing parts into the furnace. Drying time will vary depending upon temperature and atmospheric humidity. Normal drying time is one to three hours.

If the paint becomes thickened in the course of time due to evaporation, the addition of Condursal Thinner will restore the normal viscosity. The paint should be thinned only to such an extent that it can again be coated like semi-fluid oil paint; an excessive thinning would impair the protective effect of Condursal Z0095.

Removal of Residues:

After heat treatment, the residues of Condursal Z0095 can easily be removed by washing in hot water.

Cleaning of brushes and other equipment:

For cleaning brushes, it is recommended that Trichlorethylene or Condursal Thinner be used, but NEVER water.

Storage:

The can must be tightly sealed after each application, and prevented from freezing.